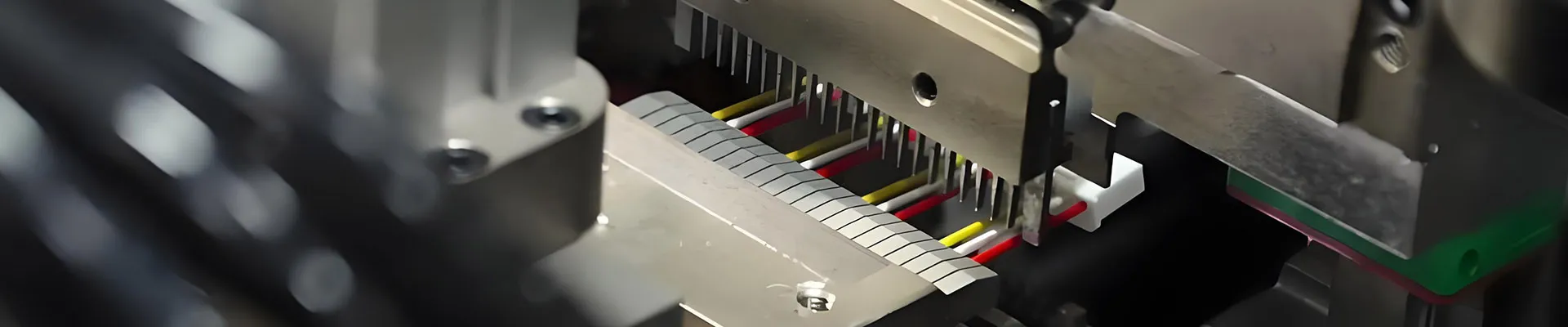

Combining terminal crimping and housing insertion into a single automatic process simplifies wire harness production while improving consistency and efficiency. This wire processing machine handles wire cutting, stripping, crimping, and the insertion of housings, making it suitable for producing multi-core cables, shielded wires, and high-temperature electronic wires. Its adaptability ensures seamless integration into various wire manufacturing workflows.

To produce high-quality wire harnesses for multi-core and shielded cables is necessary to employ a streamlined process that integrates multiple cable processing functions. This model of wire terminating machine combines cutting, stripping, terminal crimping, and housing insertion into a single automated workflow.

High-speed cable assembly involves multiple processes that need to be executed with precision and efficiency. Our crimping and housing insertion equipment integrates cutting, stripping, crimping, tinning, and housing placement into a single streamlined operation.

Precision and flexibility are crucial for assembling wires of varying lengths in high-speed production environments. This model of wire terminating machine integrates cutting, stripping, terminal crimping, tinning, and housing insertion into one workflow.

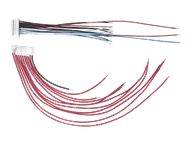

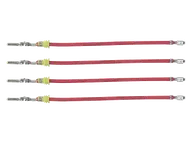

High-volume cable assembly demands precision and efficiency, especially for wires requiring two-sided wire processing. This wire terminating equipment integrates cutting, stripping, crimping, and housing insertion for both ends of the wire, offering configurations such as crimping with tinning, dual housing insertion, or creating long and short wire setups.

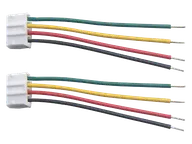

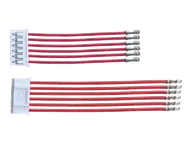

Our 2-sided crimping & 1-sided housing insertion solution supports two sides crimping and single-side housing insertion, making it ideal for producing complex wire harnesses. Each wire can be individually configured for length, providing a practical approach to handling diverse cable requirements.

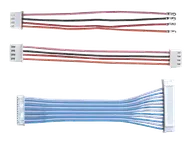

Cable assembly processes demand precision and efficiency, especially when handling diverse wire configurations. To tackle this challenge our 2-sided crimping & 1-sided seal insertion/housing insertion machine integrates multiple operations, including cutting, stripping, 2-sided crimping, and single-sides seal or housing insertion, into one cohesive system.

Cable assembly processes require precision and efficiency, especially when handling diverse wire configurations. Our Dupont wire crimping & housing insertion machine integrates multiple wire processing operations, including cutting, stripping, 2-sided crimping, and single-sided seal or housing insertion, into one system.

Engineers with over 10 years of expertise in wire harness processing ensure innovative and reliable solutions.

Reliable equipment designed to optimize automation and efficiency in wire harness production.

Backed by more than 10 years of experience, we specialize in designing and manufacturing innovative wire processing equipment tailored to meet evolving industry needs.

Customizable features and modifications address unique production requirements across various industries.