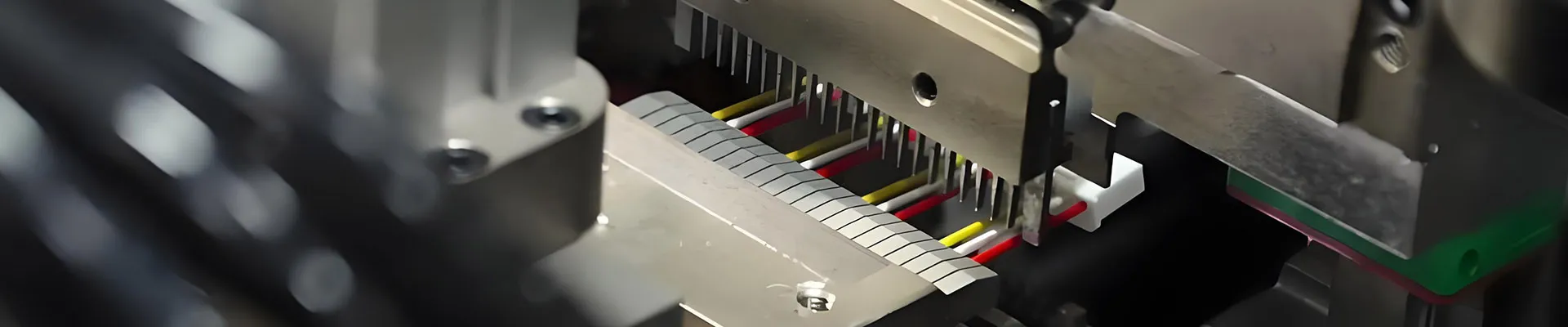

Our 2-sided crimping & 1-sided housing insertion solution supports two sides crimping and single-side housing insertion, making it ideal for producing complex wire harnesses. Each wire can be individually configured for length, providing a practical approach to handling diverse cable requirements. With a crimping capacity of 2,000 crimps per hour, this wire terminating machine ensures efficiency and consistency in processing 18AWG to 28AWG wires.

| General | Model | RH-013CC |

|---|---|---|

| Dimensions (L×W×H) | 1700×1600×1800mm | |

| Weight | Approx. 900kg (without wire pay-off and vibrating plate) | |

| Power Supply | AC220V 50Hz | |

| Rated Current | 15A | |

| Power | 3kW | |

| Air Pressure | 0.4-0.6Mpa (the air must be filtered and dried) | |

| Space Requirement | 2.5×2m | |

| Crimping Force | 2T | |

| Functions | Crimping Capacity | 2000 crimps/hr (depending on terminal housing and wire) |

| Wire Processing | Wire cutting, One-sided full stripping, Two-sided full stripping, Two-sided half stripping, One-sided crimping, Two-sided crimping, One-sided crimping + one-sided housing insertion | |

| High-precision crimping, stripping and tinning by using ball screw mechanism | ||

| Control System | LCD display, single-chip microcontroller | |

| Detection Devices | Crimp test, wire shortage detection, air pressure test, paper winding inspection | |

| Auxiliary Equipment | Crimp terminal waste / wire strip waste collector, paper winder, air storage buffer tank | |

| Operation Control | Wire feeding, cutting, stripping and movement are controlled via touch screen | |

| Optional | Pressure Measuring Device | Used to measure terminal crimping pressure |

| Application Range | Cutting Length | 35-1000mm (customizable) |

| Stripping Length | Front:0.5-15mm, Rear: 0.5-7mm | |

| Wire & Cable Type | Electric wire, high temperature cable, Teflon insulated cable (AWG28#-AWG18#) |

Intelligent robotic clamping provides stable wire alignment and precise feeding, ensuring every wire maintains its configured length and achieves consistent results.

Tailored to process a wide range of wires, from PVC and silicone to Teflon-coated and halogen-free types, it handles 18AWG to 28AWG wire specifications easily.

A built-in error detection system displays real-time alerts on an intuitive touch screen, allowing operators to quickly identify and address issues without disrupting production.

Several senior R&D engineers with more than ten years of experience in wiring harness processing.

Reliable equipment designed to optimize automation and efficiency in wire harness production.

Backed by more than 10 years of experience, we specialize in designing and manufacturing innovative wire processing equipment tailored to meet evolving industry needs.

Customizable features and modifications address unique production requirements across various industries.