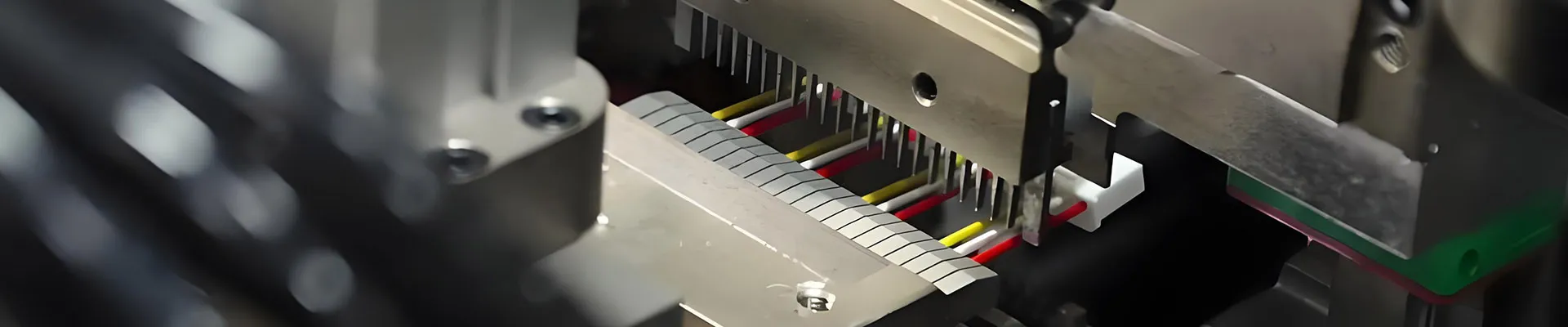

This wire terminating system automates the wire processing workflow, completing tasks such as stripping and terminal crimping in a seamless operation. Designed for communication ribbon cables and terminal types such as PH, XH, EH, and ZH, it ensures precision and stability with its advanced components.

| General | Model | RH-08A |

|---|---|---|

| Dimensions (L×W×H) | 700×500×1400mm | |

| Weight | Approx. 190kg | |

| Power Supply | AC220V 50Hz | |

| Rated Current | 5A | |

| Power | 1.1kW | |

| Air Pressure | 0.5-0.8Mpa (the air must be filtered and dried) | |

| Working Conditions | Ground is flat, leveled and dry, and not exposed to direct sunlight | |

| Functions | Crimping Capacity | 1400 wires/hr for cables with 2 to 10 cores (depending on feeding speed) |

| Crimping Force | 2T (customizable) |

The control system is powered by Mitsubishi PLC and Panasonic servo motors, ensuring precise operations and reliable performance for all wire processing tasks.

Stability and accuracy are enhanced with the inclusion of Taiwan TBI ball screws and Taiwan Shako solenoid valves, providing consistent results and improved efficiency during production.

Several senior R&D engineers with more than ten years of experience in wiring harness processing.

Reliable equipment designed to optimize automation and efficiency in wire harness production.

Backed by more than 10 years of experience, we specialize in designing and manufacturing innovative wire processing equipment tailored to meet evolving industry needs.

Customizable features and modifications address unique production requirements across various industries.