Stripping and terminal crimping machines have an important role in modern cable assembly. With a focus on making the process more efficient, we have developed a wire terminating machine that integrates both wire stripping and terminal crimping into one seamless operation. Designed to handle tasks with precision up to 0.01mm, this solution simplifies the production of computer cables, multi-core wires, and terminals, ensuring consistent and reliable results for high-demand applications.

| Model | RH-900S |

| Dimensions (L×W×H) | 330×300×300mm |

| Weight | 50kg |

| Power Supply | AC220V |

| Motor | 0.55kW, 3.1/2.0 |

| Crimping Force | 1500kg |

| Stroke | 30mm |

| Throat Height | 90mm |

| Max. Feeding Distance | 20mm |

| Stripping Length | 1.0-12mm |

| Wire Size | AWG16-AWG34 |

The integrated process performs stripping and crimping simultaneously, reducing production time while maintaining consistent performance for various cable types.

Compact and lightweight with variable frequency control, it minimizes noise and energy consumption, providing a sustainable and ergonomic solution.

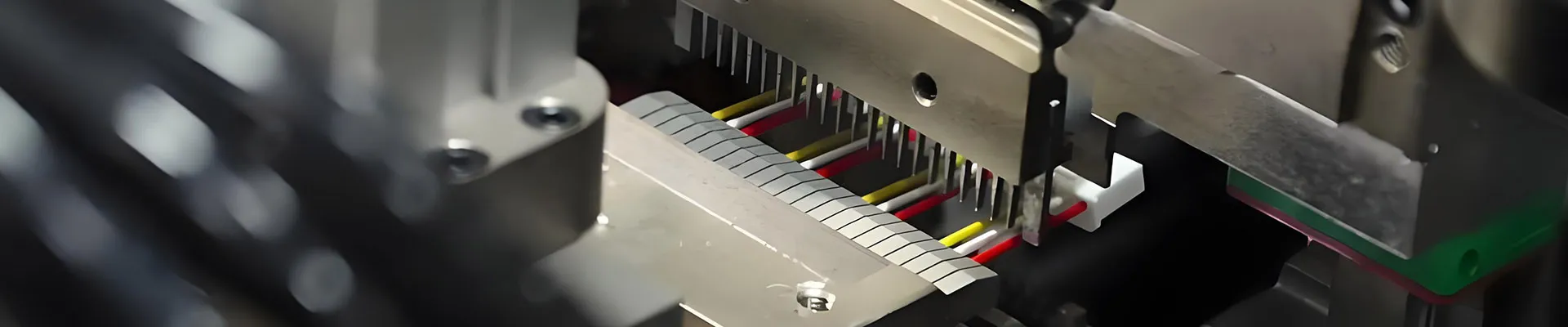

Adjustable stripping blades allow precise micro-adjustments, ensuring consistent accuracy across all wire types.

An efficient waste removal system extracts stripped insulation debris, keeping the workspace clean and organized.

Several senior R&D engineers with more than ten years of experience in wiring harness processing.

Reliable equipment designed to optimize automation and efficiency in wire harness production.

Backed by more than 10 years of experience, we specialize in designing and manufacturing innovative wire processing equipment tailored to meet evolving industry needs.

Customizable features and modifications address unique production requirements across various industries.