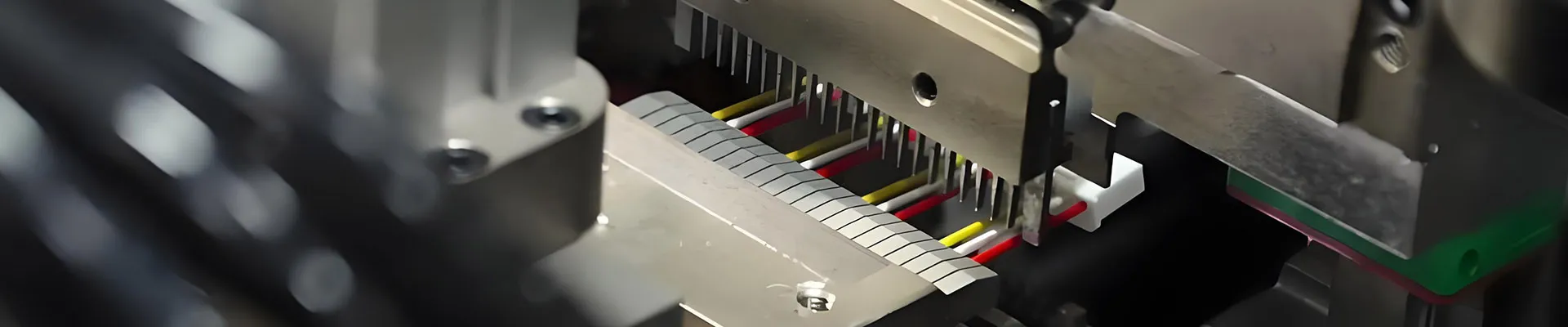

To address the need for efficient and precise cable assembly, this automatic wire terminating machine combines fully automated stripping and terminal crimping with the option for single stripping. Its mechanical transmission structure ensures consistent performance, while simplified adjustments make it suitable for a variety of production scenarios.

| Model | RH-1200 |

| Dimensions (L×W×H) | 360×390×390mm |

| Weight | 75kg |

| Power Supply | AC220V 50Hz |

| Motor | 0.55HP, 3.1/2.0A |

| Crimping Force | 1500kg |

| Stroke | 30mm (optional 40mm) |

| Stripping Length | 1.5-10mm |

| Wire Size | AWG16-AWG34 |

Its variable frequency control enhances energy efficiency and reduces noise, making it an eco-friendly solution for cable assembly.

Cassette-style mold design allows quick and simple mold changes, minimizing downtime and ensuring smooth transitions during cable production.

Several senior R&D engineers with more than ten years of experience in wiring harness processing.

Reliable equipment designed to optimize automation and efficiency in wire harness production.

Backed by more than 10 years of experience, we specialize in designing and manufacturing innovative wire processing equipment tailored to meet evolving industry needs.

Customizable features and modifications address unique production requirements across various industries.